- Why Verature?Find out why Verature is the best system for continuous contractor compliance.

- Arrive, Work & Stay Safe

- Removes Paper & Spreadsheets

- Tracks Key Contractors

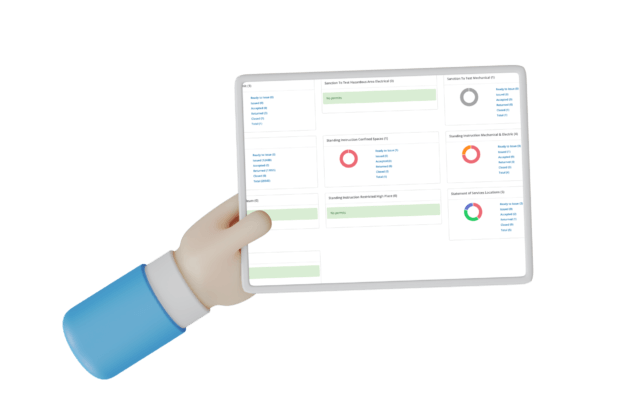

- Instant 360 Visibility

- Contractor Management Dashboards

- Why Contractor Management Software

- Our Customer Reviews

- Pricing

We don’t hide behind fancy sales teams before we tell you, our prices.- Clients

See who we are working with and what they have to say about Verature.- Resources

Check out our blog, useful guides, whitepapers and product videos.- Prequalification and Induction Guide

- Contractor Compliance Guide

- Mini-Audit your Permit to Work System

- Health and Safety Audit Checklist

- Resource Library

- Blog

Book a demo

Permit to Work System Guide for Safe Work Practices

Introduction to Permit to Work Systems

Permit to Work (PTW) systems are essential tools in managing workplace safety, especially in environments where high-risk activities take place. These systems are designed to ensure that hazardous work is conducted under controlled and safe conditions. PTW systems require detailed planning and communication between management, supervisors, and workers, outlining the work to be done, the hazards involved, and the necessary precautions. They play a critical role in preventing accidents and ensuring that all safety protocols are followed, thus safeguarding the health and safety of everyone involved in the operation.

Why Permit to Work Systems Are Necessary

Enhancing Workplace Safety

Permit to Work (PTW) systems are crucial in high-risk work environments to ensure that all safety measures are thoroughly planned and implemented before any potentially hazardous work begins. They help in identifying specific risks and establishing control measures to mitigate them, significantly reducing the likelihood of accidents and injuries.

Facilitating Effective Communication

A PTW system fosters clear and effective communication between management, workers, and all other parties involved in the work. It ensures that everyone understands the work scope, the associated risks, and the safety precautions that must be taken. This shared understanding is vital for the safety and efficiency of work operations.

Ensuring Compliance and Accountability

Implementing a PTW system helps organisations comply with health and safety regulations, demonstrating a commitment to maintaining a safe work environment. It also establishes accountability, as the system requires specific individuals to authorise, supervise, and carry out the work.

Coordination of Work Activities

In complex work environments where multiple tasks may occur simultaneously, PTW systems are essential for coordinating activities to prevent hazardous interactions. They help manage the timing and sequence of operations to ensure that safety is not compromised.

Continuous Risk Management

PTW systems contribute to a culture of continuous risk management by requiring regular reviews of the work and its risks. This dynamic approach allows for adjustments to be made in response to changes in the work environment or task scope, ensuring ongoing safety.

By incorporating these elements, a PTW system becomes an indispensable part of managing workplace safety, particularly in sectors where the potential for severe incidents is high. It is a comprehensive approach that protects workers, facilitates compliance, and promotes a safety-first culture.

Defining a Permit to Work

A Permit to Work (PTW) is a formal document that specifies the work to be done, the hazards involved, and the necessary safety precautions. It covers various aspects such as the type of work, the location, the equipment and Personal Protective Equipment (PPE) required, and the measures to mitigate identified risks. Additionally, the PTW outlines the process for job completion and requires authorization from a competent authority, ensuring that all safety protocols are observed before, during, and after the execution of high-risk tasks.

When is a Permit to Work Required?

Permit to Work (PTW) systems are integral in ensuring safety in the workplace, particularly in high-risk industries or activities. They are designed to manage tasks that pose significant hazards to workers and the environment by outlining specific precautions and protocols. The necessity for a PTW system arises from the need to carry out work safely and efficiently, where clear communication and detailed planning are paramount.

Scenarios Requiring a Permit to Work

A PTW is required in various scenarios to mitigate risks associated with hazardous work. Some of these scenarios include:

- Hot Work: Activities like welding or using open flames that could ignite fires. Workers involved in hot work must be adequately trained and briefed on safety practices to prevent accidents.

- Cold Work: Tasks that do not involve fire or ignition but still pose risks, such as chemical cleanups or heavy lifting.

- Confined Spaces: Work in areas like tanks, vessels, or canals, where there’s a danger of oxygen deficiency or exposure to toxic substances. Entry and work in these spaces require strict safety measures.

- Electrical Work: Handling electrical components or systems, which involves risks of electrocution or fire. An electrical work permit ensures all safety precautions are in place.

- Working at Heights: Tasks performed above ground level, where falls could occur. This includes work on scaffolding, roofs, or ladders, necessitating measures to prevent falls.

- Lock Out Tag Out (LOTO): Procedures to ensure that machines are properly shut off and not started up again before the completion of maintenance or servicing work, minimising the risk of injury from unexpected energization.

Types of Work Permits

Work permits are categorised based on the nature of the tasks and the specific hazards involved. Common types of work permits include:

- Hot Work Permit: For operations involving or generating heat or ignition sources.

- Cold Work Permit: For tasks involving non-flammable hazards.

- Confined Space Permit: For work within enclosed or semi-enclosed spaces.

- Electrical Permit: For activities involving electrical work.

- General Permit: Covers hazardous work not specifically categorised under other permits.

Importance of PTW Systems

PTW systems are not just about regulatory compliance; they are about ensuring that every aspect of the work, from hazards to precautions, is thoroughly assessed and managed. They provide a structured approach to hazard identification, risk assessment, and control measures, ensuring that work is conducted safely, efficiently, and in accordance with established safety standards.

In essence, a Permit to Work is a cornerstone of safety management, serving as a formal record that certain hazardous work has been authorised and that all necessary safety measures have been considered and implemented. By clearly defining the scope, precautions, responsibilities, and procedures for hazardous work, PTW systems play a critical role in preventing accidents and protecting workers.

Key Components of a Permit to Work System

Incorporating a Permit to Work (PTW) system within an organisation, especially one that engages in high-risk activities, is crucial for ensuring workplace safety and regulatory compliance. A PTW system is a structured approach that defines the necessary steps and precautions for carrying out specific hazardous tasks. Let’s delve into the key components that should be included in a PTW,

Key Components

- Authorization: This is the foundational element of a PTW system, requiring approvals from designated personnel at various stages of permit management to ensure that the work is necessary and can be done safely.

- Roles and Responsibilities: Clear definitions of roles for all individuals involved in the task are essential. This ensures everyone understands their duties and the part they play in maintaining safety.

- Hazard Identification: A thorough assessment of potential hazards associated with the task at hand, including environmental, chemical, physical, and ergonomic risks.

- Task Description: Detailed information about the task, including scope, timeline, and specific step-by-step instructions, ensuring that all parties have a clear understanding of the work to be performed.

- Risk Assessment: A comprehensive evaluation of safety protocols, possibly including site audits, equipment checks, and personnel training, tailored to the job’s specific requirements.

- Status Records: A system to track the permit’s status—whether it’s open, closed, cancelled, revoked, or reissued—provides transparency and accountability throughout the task’s duration.

- Precautionary Measures: Identification and implementation of safety measures to mitigate identified hazards, ensuring that risks are managed effectively.

- Personal Protective Equipment (PPE): Listing the necessary safety gear required for the task, which could range from gloves and helmets to specialised respiratory equipment, depending on the job’s nature.

- Permit Sign Off: The final step in the PTW process, where the work’s completion is confirmed, and the permit is officially closed, ensuring that all tasks have been performed safely and according to the outlined procedures.

Implementing a PTW System

Implementing a PTW system involves more than just understanding its components. Organisations must emphasise the importance of the system, provide comprehensive training, ensure no job starts without a validated permit, and manage completed permits properly. Digitization, such as solutions offered by Safetymint, can streamline this process, making it more efficient and effective by providing real-time information, a centralised database for permit activities, and enhanced collaboration tools for instant safety updates.

The PTW system is not just a procedural formality but a critical component of an organisation’s safety culture. It ensures that hazardous work is conducted under controlled conditions, reducing the risk of accidents and ensuring compliance with safety regulations. For organisations looking to implement or refine their PTW systems, exploring software solutions like Safetymint can provide the efficiency, oversight, and compliance needed in today’s fast-paced and safety-conscious work environments.

Integrating a Permit to Work system with contractor management and compliance software, like Verature, can significantly enhance the PTW process’s efficiency and safety compliance. Verature offers a streamlined approach to managing contractor requirements, ensuring all safety and compliance measures are met before work begins. This seamless transition from general PTW considerations to the specific capabilities of Verature underscores the importance of utilising advanced software solutions to ensure workplace safety and compliance. For a deeper understanding of how Verature can support your PTW system, visit Verature.

In conclusion,

Integrating a Permit to Work system with comprehensive contractor management and compliance software like Verature enhances safety, efficiency, and compliance across operations. Verature automates critical aspects of contractor management, ensuring all safety protocols are adhered to before any work commences. This approach not only streamlines the PTW process but also significantly reduces administrative burden and increases operational transparency. For organisations looking to elevate their safety and compliance standards, exploring Verature’s offerings presents a strategic advantage.

Empower Your PTW System with Verature: Elevate Safety and Compliance Now

For a detailed exploration of how Verature’s contractor management and compliance software can streamline your Permit to Work processes, ensuring maximum safety and efficiency, click here to learn more.

Book a demoFind out if you’re ready with our Verature Onboarding Kit

Not sure if Verature is right for you? We understand it’s not easy to make a decision on a new system, but that’s why we’ve created our Onboarding Kit to make that that process simple.

Check our package details

Find out no matter what package you choose, you’ll be getting the best features you need for you and your team so you can have continuous contractor compliance.

Make it your own

You’ll get to see and choose your customisation options, and check out the available add-ons and extras so the system is exactly what you want and need.

Quickly getting you started.

Keeping this guide with you, and working closely with us, we can walk you through each step so you can be completely up and running with your own Verature system.

More reasons to use Verature

It’s easy to get started.

Step 1

Book a demo of Verature with the team.

Step 2

We’ll chat through your requirements and see if Verature is right for you.

Step 3

We’ll send you demo access and our onboarding kit to help you decide what you need.

Step 4

You decide if we’re right for you. No pushy sales calls.

Step 5

Like what you see and hear? Let’s get you onboarded with Verature!